T

teffy

Guest

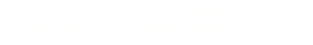

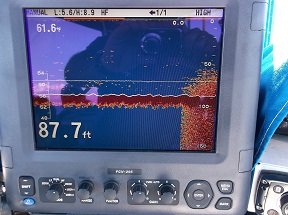

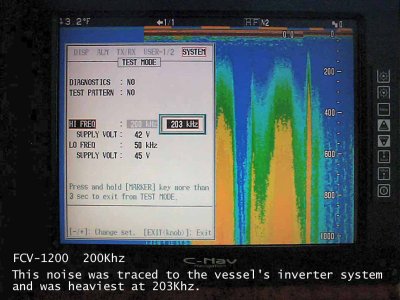

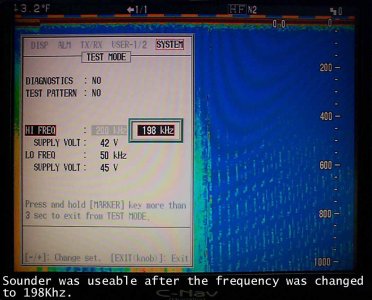

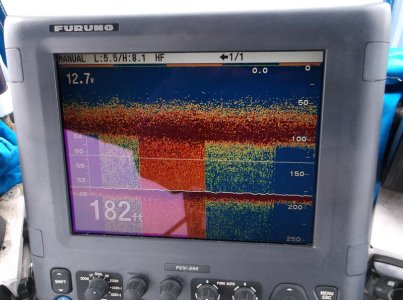

looking at some spots today and shut down the main generator was on. looked at the sounder when i started up and got this image on the sounder. fired up the engine and the noise image in the attached photo starts. u can see a excellent return destroyed by starting the engine and continue as long as the engine is operating.

i just figured this out as i always believed that i had sounder turbulence and accepted it as "it is what it is" and not the engine noise.

I monkeyed around with low med high interference settings as you can see no difference

the transducer cable run is next to the engine instrumentation cable would this be an issue?

the engine vibrates normally at idle would that affect the transducer?

where would you start to troubleshoot?

i just figured this out as i always believed that i had sounder turbulence and accepted it as "it is what it is" and not the engine noise.

I monkeyed around with low med high interference settings as you can see no difference

the transducer cable run is next to the engine instrumentation cable would this be an issue?

the engine vibrates normally at idle would that affect the transducer?

where would you start to troubleshoot?