Hi Furuno team,

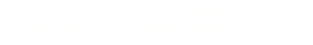

Could you please confirm whether the NAVpilot-711C (FAP-7011C control head + FAP-7002 processor) supports an analog rudder control output of −10 V to +10 V, similar to what is documented for the NAVpilot-1000? I attached a screenshot from the NAVpilot-1000 specs showing “Rudder control (analog): 0–5 V (min), −10 to +10 V (max) (5 mA max).”

My application

What I can’t find in the 711C docs

Walter Andreis

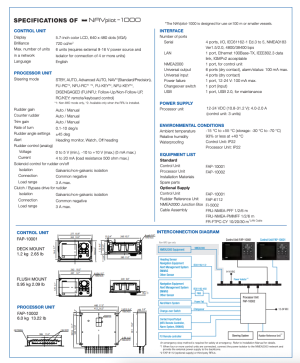

(screenshot from NAVpilot-1000 spec page, and the actual PWM controller that I'm using is attached)

Could you please confirm whether the NAVpilot-711C (FAP-7011C control head + FAP-7002 processor) supports an analog rudder control output of −10 V to +10 V, similar to what is documented for the NAVpilot-1000? I attached a screenshot from the NAVpilot-1000 specs showing “Rudder control (analog): 0–5 V (min), −10 to +10 V (max) (5 mA max).”

My application

- Workboat with hydraulic steering.

- The vessel’s proportional control is achieved by feeding a −10 V…+10 V command into a third-party PWM valve driver, which then modulates the hydraulic solenoid valves proportionally (greater helm amplitude = faster flow; smaller amplitude = slower flow).

What I can’t find in the 711C docs

- On the 711C I only see the SOL-A / SOL-B / COMMON connections to drive solenoids directly. If these are simple ON/OFF outputs, they would bypass my external PWM driver and could introduce “jerks” in the hydraulics rather than proportional control.

- Does the NAVpilot-711C provide a dedicated analog rudder command output (±10 V) comparable to the NAVpilot-1000? If yes, which terminals and what menu settings enable it?

- If the 711C does not natively output ±10 V, is there an official Furuno interface module (or recommended method) to convert the 711C’s steering command to ±10 V (or 4–20 mA) for a proportional valve controller? Part numbers would be greatly appreciated.

- When using SOL-A / SOL-B, are these strictly ON/OFF drivers, or can the 711C modulate them proportionally (e.g., PWM/ramping) to act like a proportional command? If modulation is available, which parameters control the behavior (gain, rate, soft-start, etc.)?

- Do you have any application notes for integrating the NAVpilot-711C with proportional hydraulic systems that rely on an external PWM driver?

Walter Andreis

(screenshot from NAVpilot-1000 spec page, and the actual PWM controller that I'm using is attached)