Hi All,

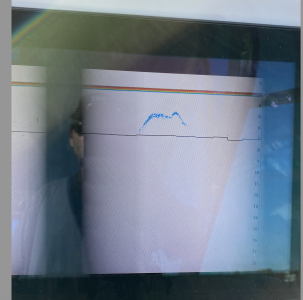

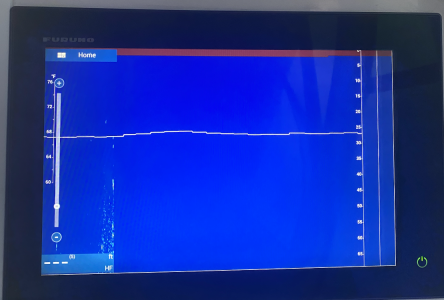

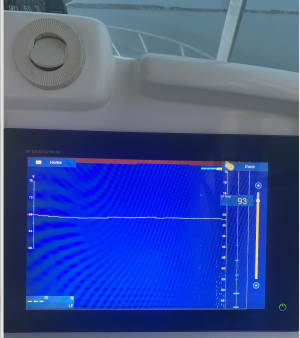

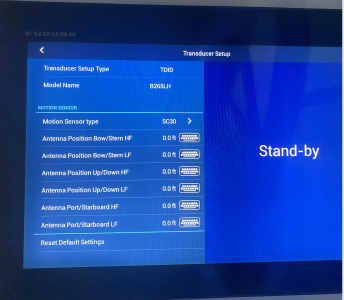

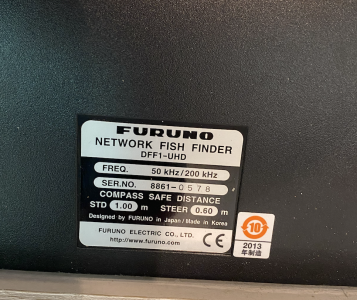

My B265LH paired with DFF1UHD stopped working suddenly during a trip. I performed a factory reset on the DFF1UHD while talking with a very helpful Furuno tech. I also did a master reset on the TZT2. After the reset I was able to read bottom again, but appears I have a false bottom and need to turn up the gain to 80+ and TVG way up to read real bottom.

Sorry for the bad screenshot, that "mark" on the screen is actually bottom without the gain turned up. You can see the false bottom at 3 feet. TIA

My B265LH paired with DFF1UHD stopped working suddenly during a trip. I performed a factory reset on the DFF1UHD while talking with a very helpful Furuno tech. I also did a master reset on the TZT2. After the reset I was able to read bottom again, but appears I have a false bottom and need to turn up the gain to 80+ and TVG way up to read real bottom.

Sorry for the bad screenshot, that "mark" on the screen is actually bottom without the gain turned up. You can see the false bottom at 3 feet. TIA