musicmanjer

Member

Aloha Furuno Wizards,

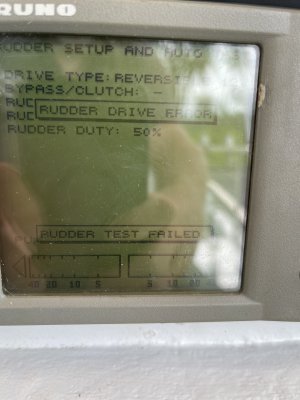

I have a NavPilot 500 system. We had a Tsunami threat so we took our boat offshore last week. The autopilot was working just fine. We came in safely, but the very next day I get a Rudder Sensor error on my display. I checked connection to the system controller and then I checked connections at the FAP 6112 sensor. I re-spliced (soldered and heat shrink) connections again at sensor ( I replaced an old FAP-6110 and used the wire from it) and checked operation again in case there was water intrusion or corrosion. Nothing. It seems since it is an analog potentiometer, it would have some feedback and not just stop working altogether?

Is there a way to test the sensor via ohm meter? Could the controller have a bad connection at the connector? What are some tests I can do to diagnose?

I depend on AP for fishing almost every day. I ordered a tested used FAP 6112 and 511 processor from a boat electronics upgrade as it is a critical tool for us. Am I missing anything??

Mahalo, Capt Jerry

I have a NavPilot 500 system. We had a Tsunami threat so we took our boat offshore last week. The autopilot was working just fine. We came in safely, but the very next day I get a Rudder Sensor error on my display. I checked connection to the system controller and then I checked connections at the FAP 6112 sensor. I re-spliced (soldered and heat shrink) connections again at sensor ( I replaced an old FAP-6110 and used the wire from it) and checked operation again in case there was water intrusion or corrosion. Nothing. It seems since it is an analog potentiometer, it would have some feedback and not just stop working altogether?

Is there a way to test the sensor via ohm meter? Could the controller have a bad connection at the connector? What are some tests I can do to diagnose?

I depend on AP for fishing almost every day. I ordered a tested used FAP 6112 and 511 processor from a boat electronics upgrade as it is a critical tool for us. Am I missing anything??

Mahalo, Capt Jerry